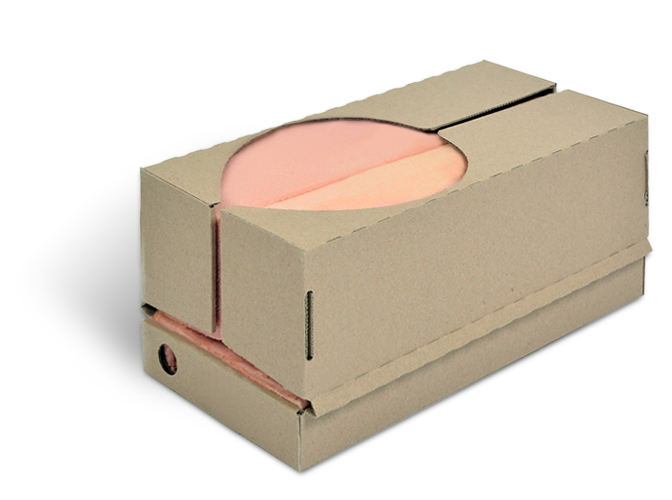

The Kuickbox: foot impressions in seconds.

The Kuickbox is the practical device for rapidly creating tailor-made shoe or orthopaedic lasts. Detailed, clean, and mobile usable. Whether it’s for low shoe, ankle-height or leg lasts.

One of the patient’s feet is simply placed into the open moulding device in the desired position. Closing the Kuickbox creates a so-called foot negative in the material inside. A toe-cap addition is then added by simply pushing into the foam. This saves time and makes the shoe last more stable. The casting box is also a container for pouring in the casting resin. The finished raw shoe lasts are then removed after hardening.

Made in Germany. And developed from practical experience.

The Kuickbox is produced in Germany. Developed by orthopaedic shoe technicians, it has a long service life when used correctly. The impression material is replaced using a cartridge system. This allows you to take moulds of several patients one after the other. Each cartridge can also be stored, transported or sent by post after removal. The cartridge is then simply reinserted into the Kuickbox for further processing, e.g. 3D scanning or pouring last foam.

Hermann Richter

Orthopaedic shoe master technician